-

2023

Delisting from the Tokyo Stock Exchange

From TOTOKU ELECTRIC CO., LTD.

Changed company name to TOTOKU INC. -

2022

Parent company changed from Furukawa Electric Co., Ltd. to TTC Holdings Co., Ltd.

-

2020

Developed high frequency measurement jig

Developed highly heat-resistant Leafconn

Constructed a new factory in the Ueda office

High heat resistant Leafconn

-

2019

Developed magnetic plated wire TIW

-

2018

Developed flexible flat cable "LEAFCONN H" conforming to next-generation high-speed interface standard "V-by-OneR US"

Developed a high-frequency IC measurement jig suitable for transmission inspection of 100G Ethernet (25Gbps) -

2017

Developed a high-performance coaxial flat cable using RUOTA.

High performance coaxial flat cable -

2016

Developed ultra-thin USB3.1 Gen2 Type-C cable ideal for large-capacity data transmission

Transferred all shares of BELTONTOTOKU Technology Limited -

2015

Started sales of a new type of anti-freezing heater "NF Auto Heater GSL Type"

-

2013

Transferred all shares of information equipment business and TOTOKU Nagaoka Co., Ltd.

Established TTI LAGUNA PHILIPPINES INC. in the Philippines -

2012

Became a subsidiary of Furukawa Electric Co., Ltd.

Through incorporation-type company split, Belton Toutoku Technology Limited Liability Company is established.

Belton Totoku Technology Limited, Belton TOTOKU Technology (HK) Limited, Belton TOTOKU Technology LLC, and TOTOKU Phillippines Inc. become affiliated companies through a share exchange.

-

2009

Relocated head office to Shimbashi, Minato-ku

Developed low-loss triple insulated winding wire

Commercialized electronic blackboard touch panel

Transferred magnet wire business -

2008

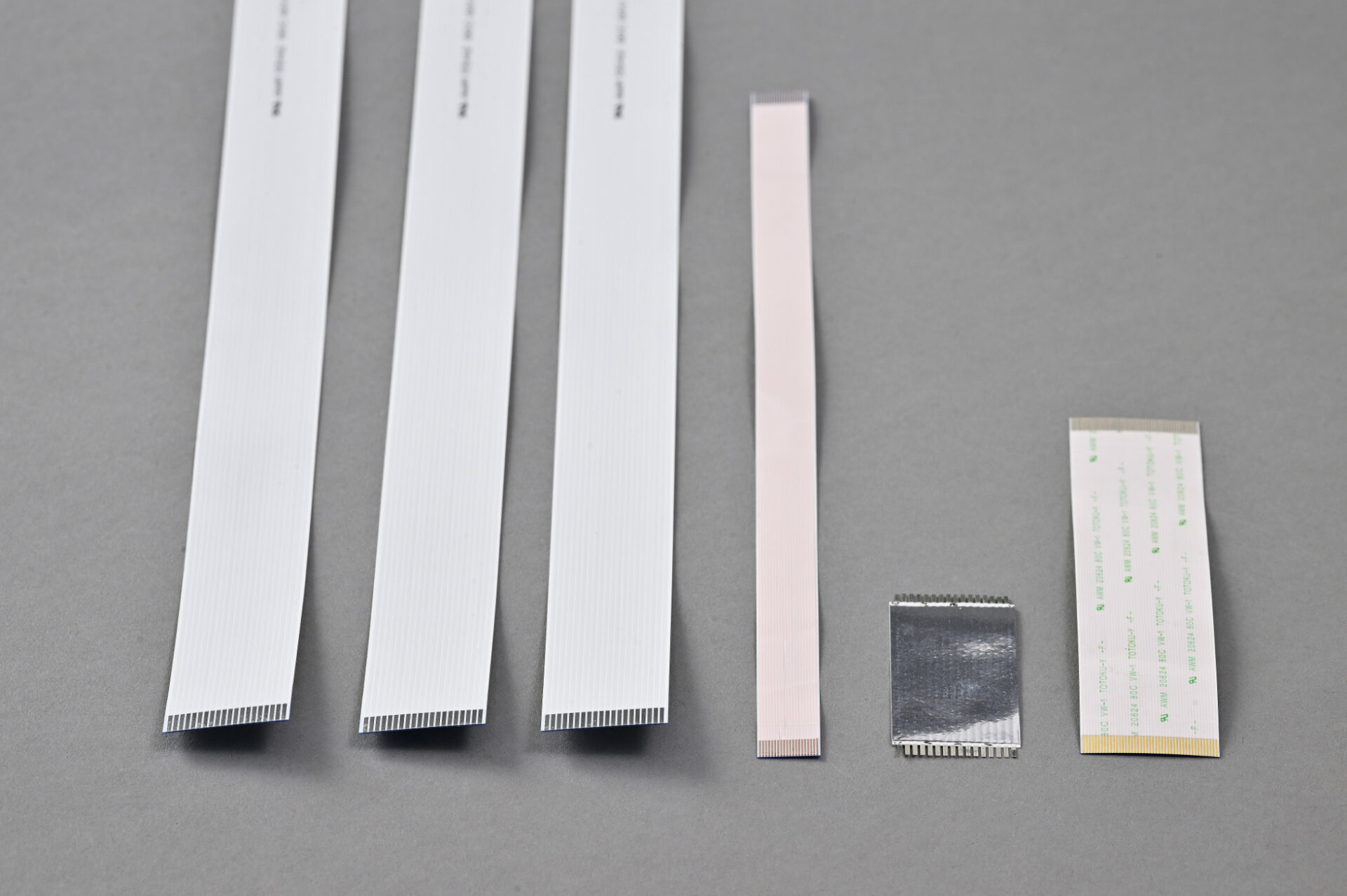

Commercialization of flexible flat cable for digital signal transmission

Commercialized ultra-fine needle type Contact Probes

For digital signal transmission

Flexible Flat Cable -

2007

Developed an ultra-high-resolution LCD (15 mega-subpixel) for mammography.

-

2006

Developed a two-way wireless IC tag system.

-

2004

Commercialization of active wireless IC tag system

-

2003

Established TOTOKU (THAILAND) CO., LTD. in Thailand

Established TOTOKU (Zhejiang) Co., Ltd. in China

TOTOKU (Zhejiang) Co., Ltd. -

2002

Development of highly heat-resistant polyimide optical fiber

-

2001

Developed a high-resolution liquid crystal display (3 million pixels) for displaying medical images.

-

2000

Developed differential cable ASM for mobile base stations

Developed wires for walking robots

-

1999

Established TOTOKU PHILIPPINES INC. in the Philippines

Developed a high-resolution CRT display (2 million pixels) for displaying medical images. -

1997

Established TOTOKU NORTH AMERICA INC. in the United States

-

1996

Developed multimedia information terminal T2.

Developed deflection yoke for completely flat CRT

Established joint venture PT. TOTOKU INDONESIA in Indonesia -

1995

Commercialized display with touch panel

Developed semi-rigid cable -

1993

Launched TOTOKU brand displays as high value-added products

brand display -

1991

Developed liquid crystal display with CRT compatible interface

Developed SM fiber cord with 8° oblique PC optical connector -

1990

Constructed a new head office building in Shinjuku, Tokyo on the occasion of the 50th anniversary of our founding.

Developed solder corrosion resistant wire

Factory festival commemorating the 50th anniversary of the company's founding

-

1989

Established joint venture TOTOKU (Malaysia) Sdn. Bhd. in Malaysia

-

1987

Started production of digital in-office cables.

-

1984

Established a new display factory in Nagaoka City, Niigata Prefecture.

Development of deflection yoke for high-resolution CRT displays -

1983

Started production of optical fiber cords with connectors.

Optical fiber cord with connector -

1982

Developed optical interface color CRT display

-

1981

Developed high resolution CRT display

Developed a liquid processing micro-slit filter (MS filter).

-

1979

Capital participation in Rongxing Wire Industry Co., Ltd. in Taiwan

Developed a CRT display for displaying Chinese characters.

Started production of self-temperature-controlled tap water freeze prevention heater as our brand product. -

1976

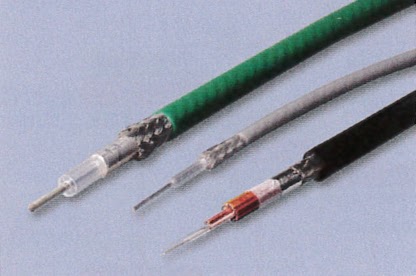

Started production of corder coaxial cables for computers.

-

1972

Commenced production of character CRT displays using high-resolution deflection yoke and deflection circuit technology.

display production line -

1970

Succeeded in developing a high-resolution deflection yoke based on the technology cultivated in television deflection yokes.

tv parts

(deflection yoke, flyback transformer, degaussing coil)

-

1967

Commercialization of tape wire used for internal wiring of computer main unit

-

1966

Developed high-strength ultrafine magnet wire

-

1965

Started manufacturing and selling degaussing coils for color TVs.

-

1963

Developed copper clad aluminum wire

-

1962

Developed magnetically plated wire for use in computers, applied for a patent and presented it at an academic conference, receiving high praise.

-

1961

Established the Ueda factory, which is also the current main factory, aiming for further progress on the occasion of the 20th anniversary of the founding

Started production of communication cables.

Their Imperial Highness the Crown Prince and his wife (currently Their Majesties the Emperor and Empress Emeritus) visit the Maruko Factory (March 1961)

Ueda Factory

-

1958

Developed heater wires for electric blankets

-

1957

Started production of TV deflection yokes and transformers.

-

1955

Developed fusible polyurethane copper wire

-

1954

Stock listed on the Tokyo Stock Exchange

-

1953

Established a position as the top manufacturer in this field, accounting for more than 5% of the domestic production volume of silk wound fine wire.

-

1952

Established Maruko factory and started operation

Started production of vinyl insulated wires

Maruko Factory (Showa 30's)

-

1945

Started production of enameled wire

-

1943

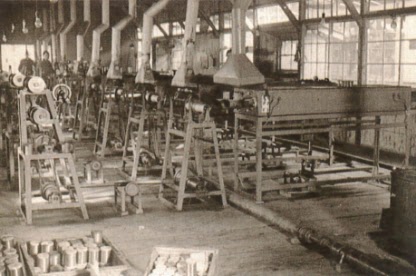

Factory moved to Nagano Prefecture, where the climate was suitable for manufacturing and developing electric wires.

Shinano factory Enamel wire baking machine -

1940

Established TOTOKU ELECTRIC Co., Ltd. in Asakusa, Tokyo for the purpose of manufacturing and selling resistance wires and various electric wires.

The business strategy was to "differentiate from other companies with distinctive products and technologies."

Started sales of silk and cotton-wrapped resistance wires

Founding President Nobuji Kobayashi