What is a semiconductor?Do you know the [tester] that supports semiconductor manufacturing?

Semiconductors are indispensable for our comfortable lives.

"Semiconductors" are installed in various familiar things such as PCs, smartphones, cars, and home appliances.Did you know that testers are essential when manufacturing semiconductors?

What is a semiconductor?

In the world, there are substances called "conductors" that conduct electricity, and substances called "insulators" that do not conduct electricity.A semiconductor is a substance with properties intermediate between a conductor and an insulator.Semiconductors such as germanium and silicon are materials that conduct electricity or not, and their electrical resistivity changes depending on the temperature.By taking advantage of this property, it has become possible to control the flow of electricity.

Semiconductors are now used in a broader sense to include individual elements such as transistors and diodes made of semiconductor materials, as well as integrated circuits (ICs) and LSIs.

The trajectory of semiconductors began in 1947 with the discovery of the point-contact transistor by physicists John Bardeen and Walter Bratten at Bell Laboratories in the United States.

In the 1950s, ICs, which are integrated circuits that combine many elements into one, and LSIs, which are large-scale integrated circuits, were developed and spread into society along with personal computers and word processors.

The semiconductor market is expected to exceed 100 trillion yen by 2030, and semiconductors are closely related to our lives and are now included in most electrical appliances.

For example, they are widespread in everyday household appliances such as smartphones, televisions, CPUs that power computers, air conditioners, and LED light bulbs, as well as social infrastructure such as bank ATMs, train operations, and communications.For example, a smartphone uses approximately 50 semiconductor chips, which are used to process and record data.

Currently, the world's annual consumption of semiconductors is said to be over 1 trillion pieces.Against a backdrop of automation and digitalization (5G, AI, cloud) in the world's industries, improvements in semiconductor technology (miniaturization, efficiency, energy saving) are becoming more important and evolving. Semiconductors are an indispensable entity that holds the key to realizing new technologies such as VR/AR, autonomous driving, and EVs.

Semiconductor size

As semiconductor technology improves, the size of semiconductor chips and circuits themselves is becoming smaller.

In 1977, the world's first personal computer had a maximum storage capacity of 48 kilobytes.Since then, storage capacity has increased dramatically, while size and weight have decreased considerably.

In modern times, 1 terabyte capacity has become commonplace, and the reason for this is that semiconductor circuit technology has improved and the "degree of integration" of semiconductors has increased.

As of 2023, Japanese semiconductor companies have begun developing semiconductors with a circuit width of 2 nanometers*, and this is attracting attention.

*(1 nanometer is 1/1 nm of 1 cm (1 cm = 10,000,000 nm), approximately 1/10 of the thickness of a single hair)

Types of semiconductors

There are three main types of semiconductors: logic semiconductors, memory semiconductors, and other semiconductors.

"Logic semiconductor" refers to a semiconductor that has basic logical operation functions.

It mainly processes data and controls devices, such as the CPU installed in smartphones and computers.

"Memory semiconductor" refers to a semiconductor that has the function of storing data.

It mainly stores data, such as DRAM installed in computers and flash memory, which is an externally connectable storage medium.

"Others" include "power semiconductors" that can handle high voltages and large currents, and "analog semiconductors" that can measure things such as light, sound, temperature, humidity, and pressure.

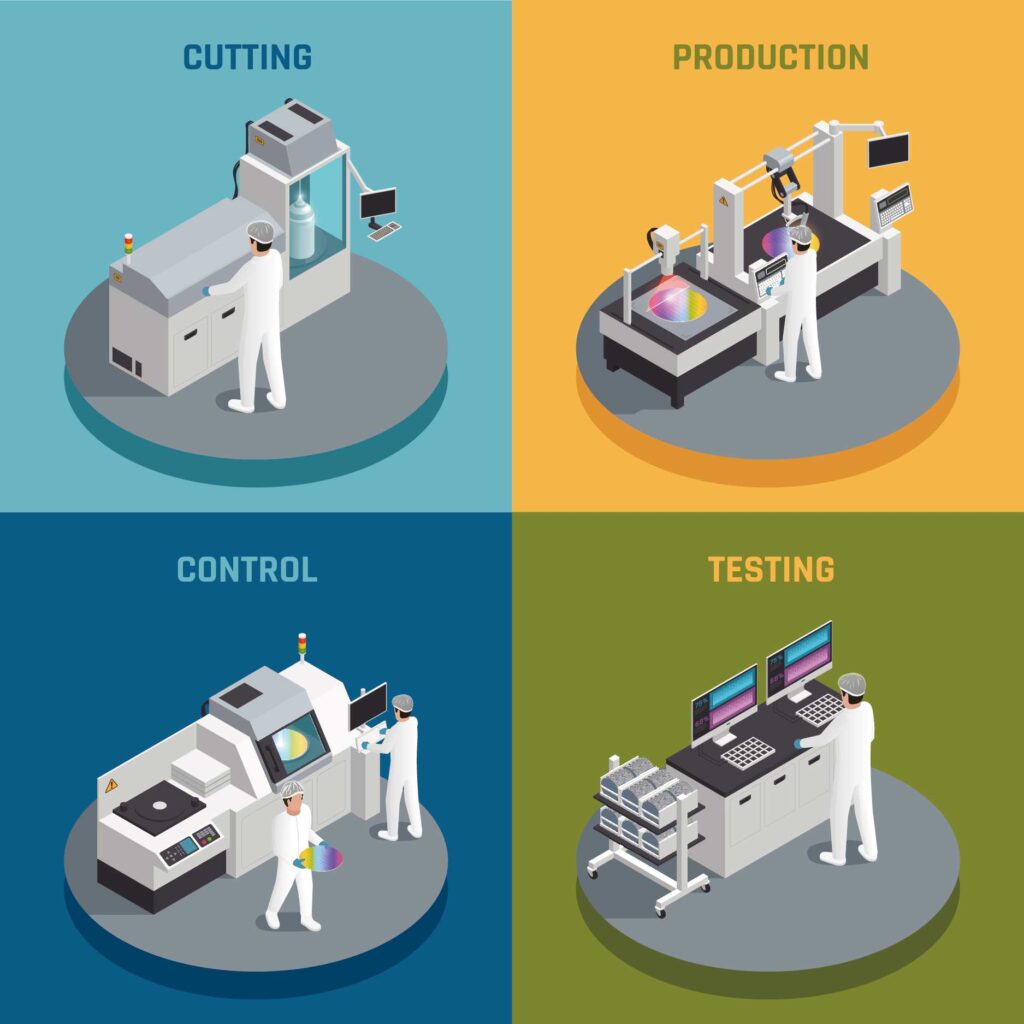

Semiconductor manufacturing process

Semiconductor manufacturing requires a total of more than 1000 processes, and each process requires an extremely high level of cleanliness.Processes can be classified into design, pre-process, and post-process.

[wafer process]...Wafer purchase, film formation, exposure and development, etching, doping, inspection, etc.

[assembly and testing process]...Dicing, wire bonding, molding, inspection, etc.

* Approximately 1000 chips were manufactured at the same time.

Reference) Semiconductor manufacturing equipment is very expensive.For example, exposure equipment necessary for manufacturing cutting-edge semiconductors

(EUV) is a market monopolized by the Dutch company ASML, and each unit costs between 20 billion and 40 billion yen.

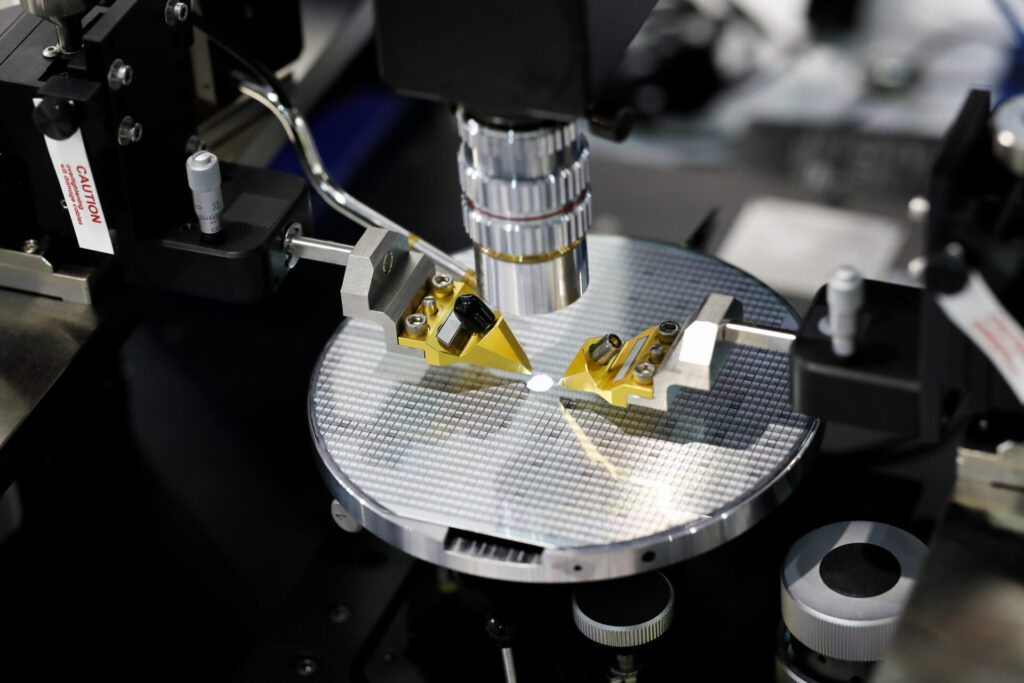

The major role of semiconductor testers

Semiconductors are called the "rice of industry" because they are essential to many products such as smartphones, computers, and automobiles.Recently, semiconductors have become increasingly sophisticated and important, so much so that they are sometimes referred to as the "brains of industry."

Semiconductors play an indispensable and important role in our daily lives, and in order to ensure their quality and reliability and provide products that are free of problems and defects, they are inspected using a "semiconductor tester."Verify that it works as designed.Depending on the type of semiconductor, testers are broadly classified into "logic testers" for logic semiconductors, memory testers for memory semiconductors, and other analog testers.

Semiconductor testers are used for various semiconductors.

・Quality assurance (test to see if it works properly)

・Eliminating defective products and confirming high performance (testing high-speed data processing performance, etc.)

・Ensuring safety and reliability (e.g. autonomous driving, medical equipment, communication infrastructure, etc.)

- Evolution of technology (development and improvement of test methods, reduction of test time)

plays a very important role.

*When the circuit width evolves from 3nm to 2nm, the time required for inspection increases by 20 times! Directly linked to semiconductor costs!

Semiconductor testers maintain the quality and reliability of the electronic devices we use on a daily basis, making our lives more convenient, safe and secure.

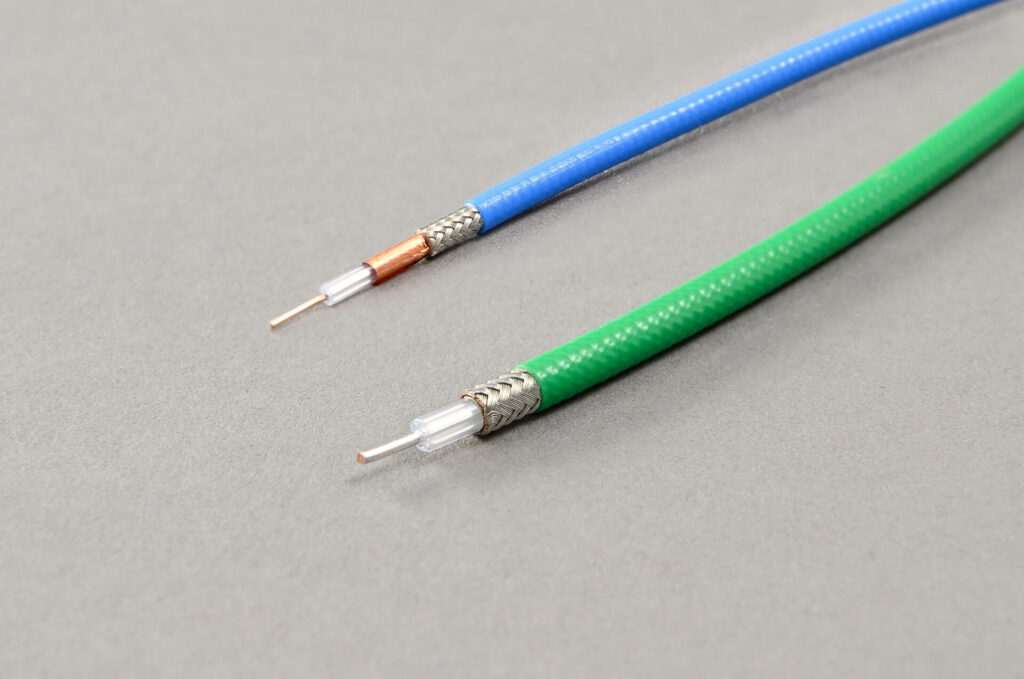

TOTOKU develops various products necessary for such semiconductor inspection.

For further information, please read Industry introduction page.

Summary

TOTOKU not only handles semiconductor-related products, but also a variety of other products that support our lives.

If you would like to know more about where TOTOKU products are used, please visit here.