Flexible Flat Cable

LEAFCONN

It is the best product for internal wiring of electronic equipment.

This is a parallel multicore wire made of rectangular conductors arranged at regular intervals and laminated with insulating tape.

All of our flexible flat cables are lead-free.

(Note) “LEAFCONN” is a registered trademark of TOTOKU INC.

All of our flexible flat cables are lead-free.

(Note) “LEAFCONN” is a registered trademark of TOTOKU INC.

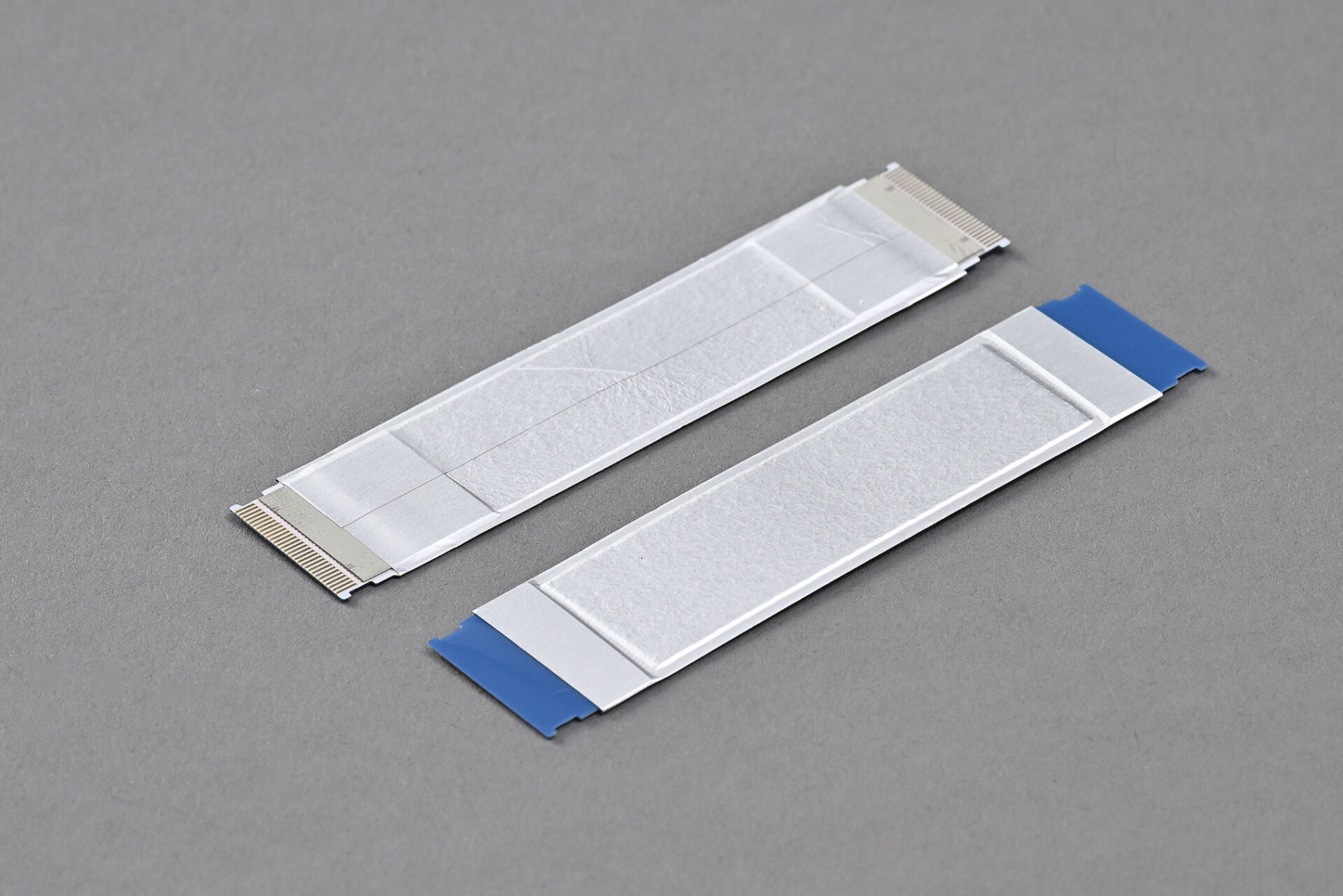

| Processing type |

|

|---|

Features

The lineup also includes a "halogen-free flexible flat cable" as an environmental measure, and a "gold-plated flexible flat cable" as a whisker-proof measure.

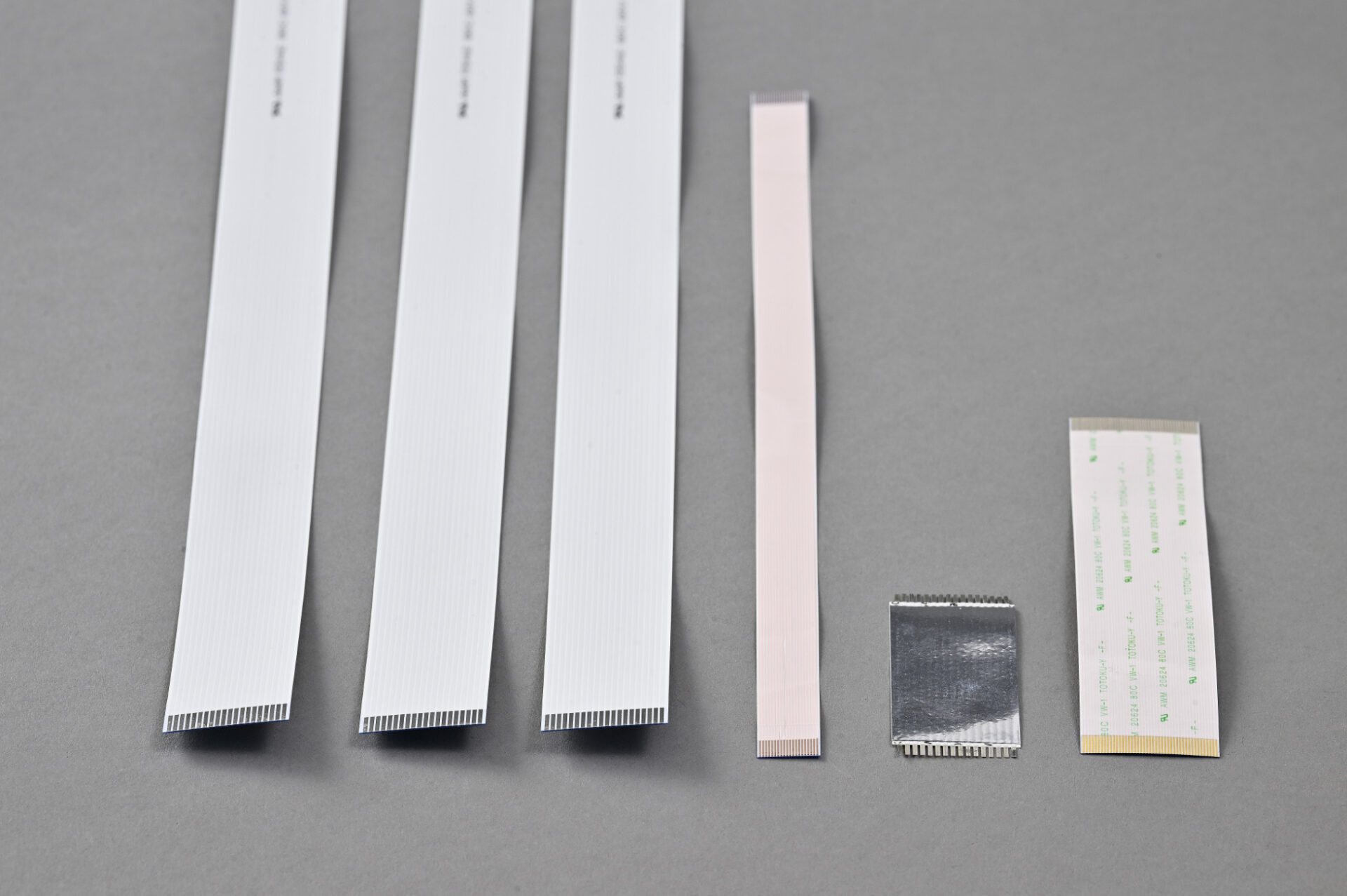

Standard flexible flat cable

- It is more economical than FPC.

- It is highly flexible and can withstand repeated bending.

- Products of any length and number of cores can be easily manufactured.

- Connections are easy because the wire itself can also be used as a connector contact.

- It has better heat dissipation than round wire and can have a larger current capacity per unit cross-sectional area.

- It can be bent into any shape.

- Wiring space is small and packaging density is improved.

Halogen-free flexible flat cable (for environmental protection)

- Contains no halogen flame retardants or antimony compounds.

- The properties, including flame retardancy, are the same as those of Leaf Con made using conventional halogen flame retardants.

Gold-plated flexible flat cable (for whisker prevention)

- There are no whiskers, ensuring connection reliability.

- Excellent contact stability for connectors, etc.

- It has excellent corrosion resistance and can be soldered.

Gold-plated flexible flat cable

Shield type flexible flat cable

Use

- Lead wires for connecting printed circuit boards of electronic devices such as printers, copiers, stereos, TVs, VTRs, telephones, and fax machines.

- Lead wire for connection between printed circuit board and electronic components

特性

| Characteristic items | 1.25mm pitch | 1.00mm pitch | 0.5mm pitch | |||||

|---|---|---|---|---|---|---|---|---|

| Conductor used (mm) | 0.1 x 0.8 | 0.05 x 0.8 | 0.035 x 0.8 | 0.1 x 0.7 | 0.05 x 0.7 | 0.035 x 0.7 | 0.05 x 0.3 | 0.035 x 0.3 |

| Use | General use | For bending | For high bending | General use | For bending | For high bending | For high density mounting | For high density mounting |

| Conductor resistance Ω/m | 0.26 | 0.6 | 0.935 | 0.3 | 0.7 | 1.1 | 1.7 | 2.2 |

| Rated current A (reference value) | 1.0 | 0.5 | 0.4 | 0.9 | 0.5 | 0.3 | 0.2 | 0.1 |

| Line insulation resistance | DC500V 100MΩ or more | |||||||

| Line withstand voltage | DC1,000V 1 minute | DC500V 1 minute | DC300V 1 minute | |||||

| Operating temperature | -30~80(105)℃ | |||||||

| 180° bend | 20+ classes | 40+ classes | 100+ classes | 20+ classes | 40+ classes | 80+ classes | 40+ classes | 40+ classes |

| Rolling (10R) | 100,000 teams | 4 million times | 10 million times | 80,000 teams | 4 million times | 8 million times | 2 million times | 2 million times |

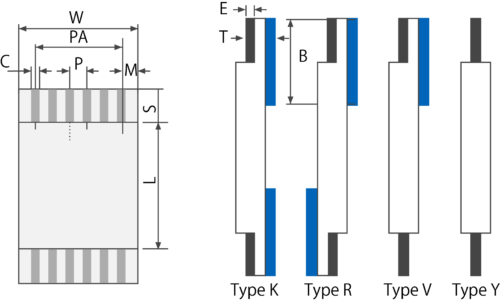

Spec.

| Item | 1.25mm pitch | 1.00mm pitch | 0.5mm pitch | |||||

|---|---|---|---|---|---|---|---|---|

| Conductor size (C×E) (mm) | 0.035 x 0.8 | 0.05 x 0.8 | 0.1 x 0.8 | 0.035 x 0.7 | 0.05 x 0.7 | 0.1 x 0.7 | 0.05 x 0.3 | 0.035 x 0.3 |

| cable type | K, R | K, R, V | K, R, V, Y | K, R | K, R, V | K, R, V, Y | K, R | K, R |

| Pitch (P) (mm) | 1.25 | 1 | 0.5 | |||||

| Number of cores (n) (pieces) | 4 to 40 | 5 to 40 | 15 to 50 | |||||

| Total pitch (PA) (mm) | 1.25(n-1) | 1.00(n-1) | 0.5(n-1) | |||||

| Finished width (W) (mm) | 1.25(n+1) | 1.00(n+1) | 0.5(n+1) | |||||

| Margin width (M) (mm) | 1.25 | 1 | 0.5 | |||||

| Strip length (S) (mm) | 2,3,4,5,6 | 2,3,4,5,6 | 2,3,4,5,6 | |||||

| Reinforcement tape length (B) (mm) | 6,8,10,15 | 6,8,10,15 | 6,8,10,15 | |||||

| Insulation length (L) (mm) | 20 to 9000 | 20 to 9000 | 20 to 1000 | |||||

| Terminal thickness (T) (mm) | 0.3±0.05 (Connector compatible type) Conductor thickness (soldering type) |

0.3±0.05 (Connector compatible type) Conductor thickness (soldering type) |

0.3±0.05 (Connector compatible type) Conductor thickness |

|||||

| Insulating tape thickness (mm) | 0.06 | 0.06 | 0.06 | |||||

| UL grade | 5542, 5543 | 5542, 5543 | 5542, 5543 | |||||

UL STYLE-5542 80℃ 60V/UL STYLE-5543 105℃ 60V

Product catalog

For more information on LEAFCONN, please download the catalog below.